The work provides some significant insights around the condition of supplier collaboration today, revealing The weather of collaboration that businesses and suppliers feel are Functioning nicely, plus the areas that current the best troubles.

In reaction to disruptions, supply chain resilience happens to be a precedence for enterprises. Supply chains require to be able to take care of disruptive situations without having breaking. To control that feat, they have to improve at collaboration.

Disconnects inside of 1 Group can build challenges, also. A “grassroots” collaboration began amongst two supply chain supervisors can lead to fast efficiency advancements, only for being snuffed out when These better during the Firm fail to comprehend the initiative’s likely. Alternatively, a collaboration settlement designed amongst two board-degree executives will fizzle out In case the supervisors chargeable for executing it Assume it is actually Yet one more brief-lived senior administration whim, if they can’t see how the collaboration will help them achieve their own aims, or whenever they absence the motivation to put extra work into your task along with their existing working day-to-working day roles.

Collaborative execution is the whole process of executing supply chain transactions within a collaborative method.[5] Suppliers will operate with potential buyers to ensure the appropriate amount of products is sent in the appropriate time as per the deal.

Align strategically Using these partners to determine joint targets and establish a compelling business enterprise circumstance for equally functions.

About the supply aspect, blog here even so, There's less and less area for brands to soak up more costs as volatile input rates put the squeeze on margins and also the marketing and advertising financial commitment necessary to differentiate branded products from non-public-label competition continues to increase.

Having said that, the retailer’s supply chain executives struggled to get acceptance for The theory from their leadership as it resulted inside the retailer carrying a far more substantial fraction on the logistics Expense.

Undertake a methodical and structured approach to define the scope, speed and targets for joint assignments, such as a clear methodology on how to measure price generation.

To stop stock-outs under this routine, both equally the maker and the retailer were being compelled to maintain higher levels of inventory on hand.

Develop a governance product focused on efficiency, implementation tracking, and hardwiring provider collaboration into core operational processes.

Develops legitimate and reputable devices of supply chain collaboration, collaborative strengths, as well as their linked constructs

Providers are fewer confident, nevertheless, that their companions is going to be prepared to put the passions in the collaboration earlier mentioned the pursuits of their very own Business.

Vertical collaboration is the collaboration when two or even more organizations from unique amounts or stages in supply chain share their tasks, assets, and efficiency details to serve somewhat related finish clients; even though horizontal collaboration is really an inter-organizational systemrelationship among two or more organizations at the same stage or phase inside the supply chain so that you can let bigger simplicity of work and cooperation towards acquiring a typical objective.[three]

All of it could feel a like it little intricate in the beginning, but you'll find three amounts of supply chain collaboration which might be suitable in your Firm.

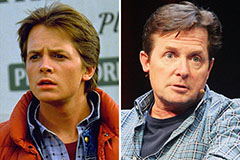

Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Brandy Then & Now!

Brandy Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!